The Ultimate Guide To Printsteals

The Ultimate Guide To Printsteals

Blog Article

The Only Guide to Printsteals

Table of ContentsThe Greatest Guide To PrintstealsThe Best Guide To PrintstealsThe 4-Minute Rule for Printsteals

Screen printing, in layman's terms, is a printing technique that entails utilizing a mesh display to move ink onto a surface, such as textile, paper, or plastic - https://packersmovers.activeboard.com/t67151553/how-to-connect-canon-mg3620-printer-to-computer/?ts=1722242185&direction=prev&page=last#lastPostAnchor. A stencil called a screen, is produced by shutting out areas where the ink should not go through. The ink is after that pushed through the open locations of the display onto the product under, developing a printed style: Apparel sector for printing designs on t-shirts, hoodies, and other garments; Promotional products market for producing things such as shoulder bag, caps, and individualized devices; Developing vibrant and sturdy outdoor and indoor indicators; Production of posters, stickers, stickers, and other visuals prints. Not ideal for intricate or highly comprehensive styles, as it can be testing to accomplish great information with this method; Can be taxing and labour-intensive, especially when multiple colours are involved; Increase manufacturing expenses for complicated jobs.

It includes a versatile alleviation plate with increased picture areas that transfers ink onto various substratums, such as paper, plastic, or film. print shops in san diego. Home plate turns on a cyndrical tube, and as the substrate travels through journalism, the inked plate rolls against it, producing the desired print. Flexographic printing offers exceptional print quality, rapid manufacturing rates, and the capacity to print on a vast range of products

Printsteals Fundamentals Explained

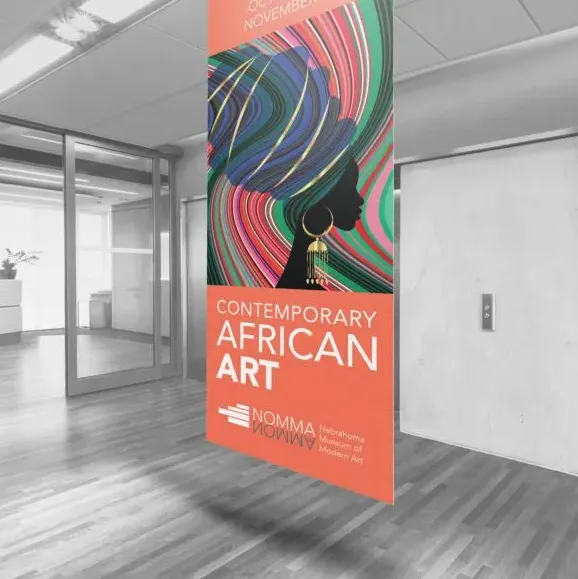

Large-format printing makes use of wide-format printers that can suit products with better size, enabling the production of prints in sizes that can vary from several feet to several meters in width. This printing technique offers top quality, eye-catching prints with vivid colours and crisp details. It is an effective marketing device for businesses, occasion organizers, and advertisers looking for to make a strong visual impact.

Relatively costly compared to smaller-scale printing approaches Logistics and installation of large-format prints can be challenging Requiring specific equipment and knowledge to manage and place the large prints properly. Inspect our overview on how to start a Large Format Printing Company. 3D printing, likewise called additive production, is a cutting-edge technology that allows the creation of three-dimensional items from electronic designs.

A 3D printer analyzes a digital layout data and constructs the physical things by adding product layer by layer until the last item is complete. https://www.storeboard.com/printsteals. This modern technology enables the production of complex and complex forms that may be challenging or impossible to accomplish with standard production methods.: Item style and advancement for quick prototyping used by developers and engineers; Utilized for developing tailored medical implants, prosthetics, and surgical models in the health care market; Manufacture lightweight and intricate parts for aircraft, decreasing weight and enhancing gas effectiveness in the aerospace industry; Fast prototyping, tooling, and even publishing practical parts for vehicles in the automotive market; Usage in jewelry making, architecture, education, and artistic productions

Fascination About Printsteals

LED UV describes a kind of UV (ultraviolet) curing technology used in printing and coatings. Unlike standard UV healing systems that make use of mercury-based lamps, LED UV employs light-emitting diodes (LEDs) as the light source. LED UV provides several advantages, consisting of power efficiency, longer life expectancy, and instant on/off capabilities. It gives off a narrow band of UV light that is concentrated on the curing process, resulting in faster and a lot more effective drying or healing of inks, finishings, or adhesives on various substrates.

Each type has its very own particular niche and market. By investigating and analyzing the target market, evaluating tools and expense factors to consider, and taking into consideration the particular printing needs of prospective customers, striving entrepreneurs can make educated choices to begin a successful printing business. By using the best printing solutions, high quality products, and outstanding customer support, a printing company can grow in today's affordable market, satisfying the varied demands of customers and making a lasting impact in the sector.

Report this page